3-AXIS PARALLEL TRAVERSE ROBOTS

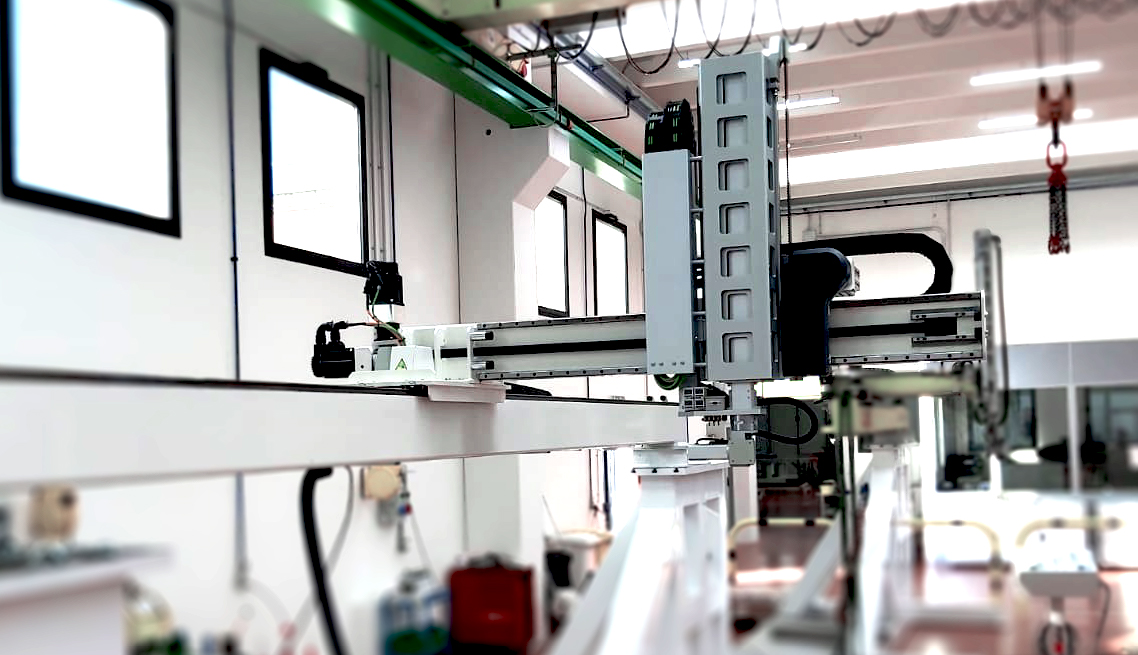

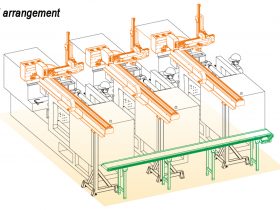

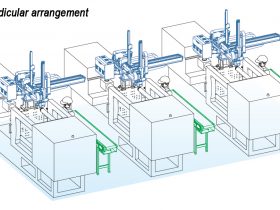

This parallel traverse model (HRXIII-150/250Si-SWi-PT) is designed to run parallel to the injection molding machine for saving space between the IMMs.

・Space Reduction

With our parallel traverse model, it’s possible to add additional IMMs to the factory, as space between IMMs can be narrowed.

・No Relocation

No need to relocate IMMs when replacing sprue pickers with parallel travers type robots.

・Less Conveyors

No need to have separate conveyors for each IMMs, therefore packing and inspecting can be performed easier.

FEATURES

The ideally designed HRX III series contributes to improving productivity in factories, generating faster take-out time and a wider range of the maximum payload.

STANDARD

- Vacuum ejector : 1 circuit

- Palletizing (up to 999 points per axis)

- Selectable home positions (1st Entry / Out-Mold / Above Mold / Backward)

- Reject circuit

- Counters (Example: Initial Reject / Sampling)

- Pass motion (speedup motion)

- Part grip : 1 circuit

- Built-in memory for mold data

(up to 1000 memories) - Smart Programming

- Initial reject

- Take out from moving platen

- Display language selector

- Main Sprue Grip: 1 circuit

- Adjustable point coordinates during the auto-run

- Customizable screen display layout

- Sampling

- Wrist flip en-route (speedup motion)

- Quick point-teaching features (Teach & Go / Point Stop / Cordinates entry)